LETS MAKE A 36-INCH TOASTER

OVEN Page 3

or

LETS MAKE A COATING CURING

OVEN FOR RIFLES

Page 3

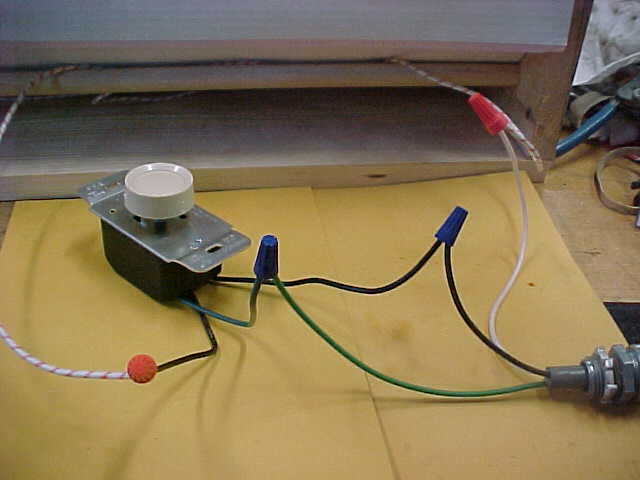

The oven temperature will be

controlled with a $4 light dimmer, wall mount style.

This shows the wiring

connections. This is just an illustration, the final

wiring will be in a "Handy" box with a cover. The power cord can be

seen in the lower right. The cord has a black, white and green wire. I used a

dimmer with a Green (ground) wire, so I connected the green wire from the

dimmer and the green wire from the power cord together. If you use a dimmer

without a ground wire, connect the green wire from the power cord to the metal

box. The black wire from the power cord goes to one of the black wires from the

dimmer while the white wire from the power cord goes to one of the wires from the

heating strip. In the picture above, the white wires with the red marks are the

heater wires. The remaining heater strip wire connects to the remaining black

wire from the dimmer.

Now cut 2 (or more) disks

having a diameter equal to the inside diameter of the oven. Drill one 1/4-inch

hole in the center of each and one hole about 1-inch from the edge. Get a piece

of 1/4-inch all-thread rod 1-inch longer than the oven along with a hand full

of 1/4-inch nuts and washers.

Above shows a Mauser action on the rod with the rod through the center

holes of the end pieces. Use a nut and washer on either side of the end pieces

and adjust them so as to place the ends atop the screws at each end. Place the

rod through the off-center holes, position the rod at the top of the oven and

hang small pieces for curing.

A 1/4-inch rod will work for

bore diameters of 6.5mm and up. For smaller bores, or if you don't like the

idea of passing a threaded rod through your barrel, use a piece of drill rod (Wholesale Tool)

and make some stop collars. Most drill rod is only available in 36-inch

lengths.

Miscellaneous Ramblings………

- The biggest

problem is getting a small (wattage wise) length of heater wire. Most

heating elements are 700 watts and larger. My oven, with 1 1/2 thick walls

works well with 200 or so watts. If you can find a 220-volt element, it

will make 1/4 of its rated wattage when used at 120 volts. This means that

if you use a 1000-watt, 220-volt element with 120-volt power it will make

only 250 watts. (Perfect)

- You may

consider using a toaster oven heater and it's associated control, or a hair dryer. If

anyone comes up with a workable idea please let

me know.

- I have not

made any firm dimensional statements, as you will have to build around the

insulation you come up with. The 6-inch (6 3/4-inch ID) insulation seems

just about right.

- Watch out

for the "paper" outer coating on some insulation as it may be

foil coated on the inside. Tear away the "paper"/foil around the

screws that may be hot-electrically.

- Wood seems

to stand 350 degrees so a wooden box 6x6x3?-inches

with a hinged lid may work.